Fossil-free graphite

Graphite is widely used in process industries, E-mobility and digitalisation. Its consumption has increased rapidly due to increased production of lithium-ion batteries globally. The graphite demand in Swedish metallurgical industries will increase due to fossil-free steel production, in which the EAF (Electrical Arc-Furnace) process is increased.

Today, all used graphite comes from natural graphite mines or fossil-based artificial production. The main purpose of this project is to develop a production process, low in energy consumption and CO2 emissions, to produce fossil-free graphite that can be used for electrodes in EAF and anodes in battery applications.

The proposed process is based on catalytic graphitization of biomass-derived biochar. Suitable catalysts will be screened, and optimization of process parameters will be conducted. Finally, a process with details parameters will be proposed.

Read about preliminary results from December 2022 here.

Weihong Yang

KTH Royal Institute of Technology

weihong@kth.se

Project information

Participants

KTH

Uppsala University

EnviGas Technology AB

Schedule

January 2022 - December 2024

Total project cost

5 943 607 SEK

The Swedish Energy Agency's project number

2021-00048

More projects

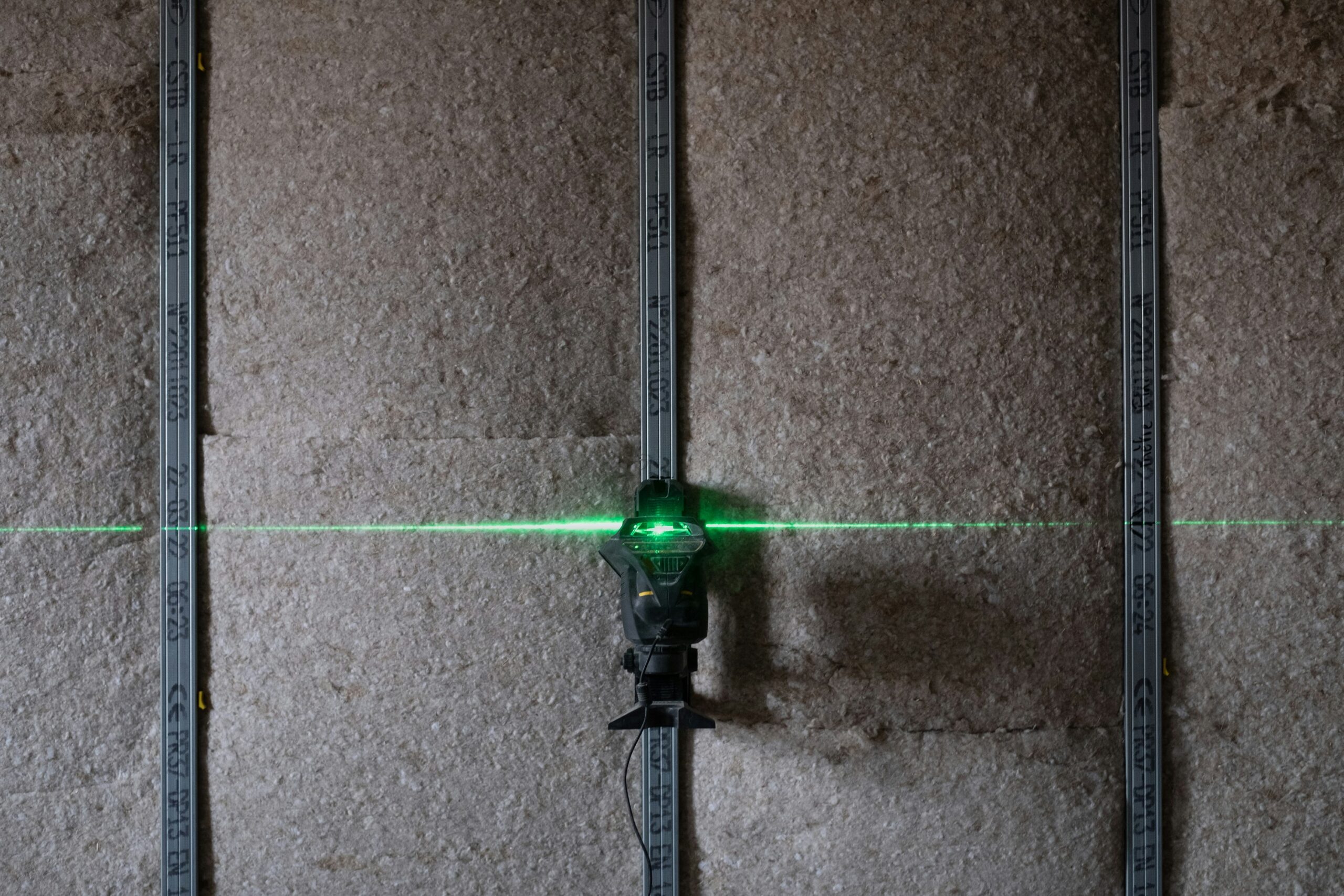

Novel bio-based, hygroscopic insulation materials for enhanced energy performance and robustness of buildings

The construction sector in Sweden stands for about 22 % of total greenhouse gas emissions. Reducing the embodied carbon in new buildings…

Manager: Maria Fredriksson

Ongoing

Paulownia – A new possibility for energy and climate transition in Sweden

How can Paulownia be commercially grown in Sweden? This project has investigated what is needed to succeed in cultivating Paulownia in Sweden….

Manager: Jarmo Spiik

Completed: 2023-04-28

CReative Construction Of DefoSSilized Value Chains – CROSS

Deep decarbonization of the society requires rethinking of the production routes and value chains with a radical switch to renewable carbon, utilizing…

Manager: Efthymios Kantarelis

Ongoing